In the dynamic world of industrial machinery and engineering, every component plays a crucial role in determining the efficiency and performance of a system. Among these components, extension springs hold a special place, as they are responsible for providing the necessary tension, support, and shock absorption in various applications.

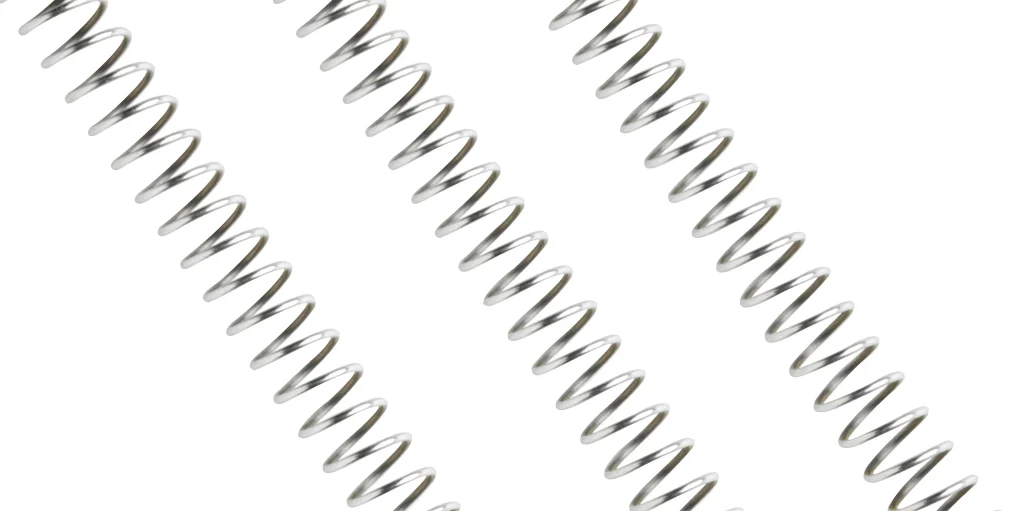

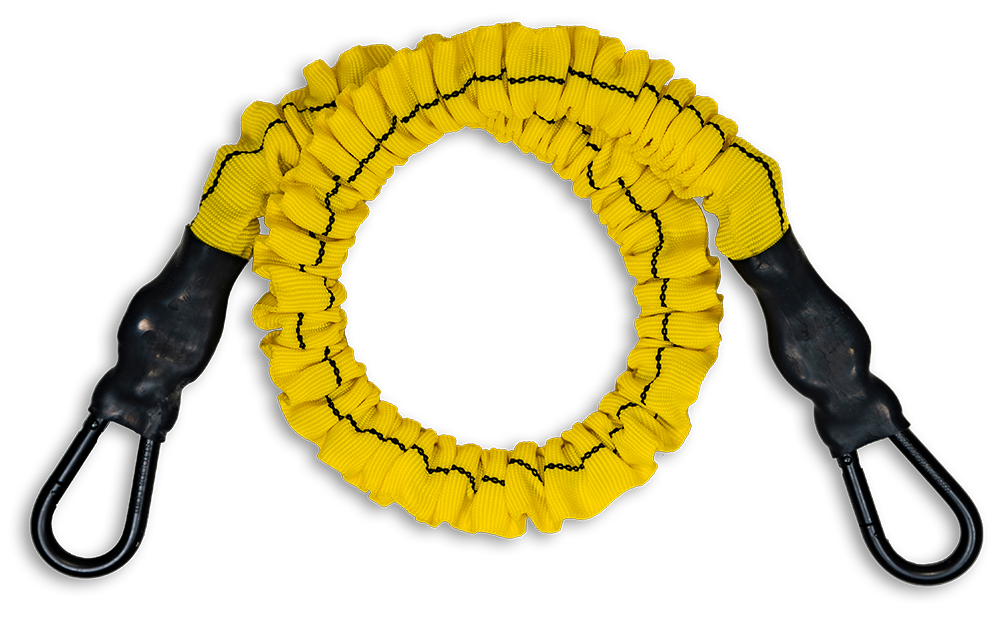

When it comes to springs, business leaders may often feel like standard extension springs, with their metal coiled design leading to some limited capabilities, are their only option. That’s no longer true with the advent of elastic extension springs, which carry some of the same capabilities as the traditional spring design with some specialized versatility.

For engineers and industry leaders, understanding the strengths of these spring designs is essential for incorporating the proper components into their processes. Let’s explore the pros and cons of each to help you make informed decisions when selecting the right springs for your industrial needs.

The choice between traditional coiled springs and elastic extension springs ultimately depends on the specific requirements of your industrial application. Consider the following factors:

In conclusion, both traditional coiled springs and elastic extension springs have their own sets of advantages and limitations. Understanding your application’s unique requirements and carefully weighing the pros and cons of each type will enable you to make the best choice for optimizing the performance and efficiency of your industrial machinery or system.

For more information on 3X Springs’ innovative line of elastic extension springs, visit our page on the elastic extension spring.

Check out our resources for more information as well.

March 3, 2025

Discover a world of valuable insights, expert tips, and exciting content right in your inbox. Sign up for our newsletter today and never miss out on our newest blog post announcements, exclusive offers, and industry news.

Contact our team today to start your journey with us!